Norms Restoration - 31 Seater Projects |

1952 AEC Regal III [2547]

2017

February Body

- 15th Feb 2017

- It just keeps coming.

- I was looking for something and discovered this.

- If this was the Leyland I would just repair it but not this bus.

- It has a layer of orminoid (bitumous sheeting) on top and water has gotten under it and caused deep rust almost all the way through the metal.

- Carle Gregory

- how you going to reprofile the go pedal?

- Norman Julian

- I have since taken all the bitumous sheeting and decided to repair this.

- Just has lots of rust craters. I will fill them in.

- It's not pretty is it!

- I have decided that I might save this.

- It is a part of this bus and their are only a few small holes that have made there way through.

- I'm therefore asking you followers, what would you do, and how would you fix it.

- Geoff Jones

- save it.........

- Craig Parkinson

- Norm it has a cover that go's over it around the peddles and steering column with a rubber mat on the bottom of the floor, no one will see it so don't worry to much about it.

- I'll send you some photos on weekend

- Norman Julian

- Yeah! That's right!

- Andrew Blacklock

- repair it = got all original pressings in it.

- Norman Julian

- Because I haven't got the right tool for the swagging I would have to use a thicker material.

- Jim Sharp

- Repair it

- James Leonard Garrod

- Heat the whole thing evenly (to reduce warpage) with a blow torch and 'Sweat' a decent covering of braze all over it. Do Not Quench, leave to cool naturally to lessen warpage.

- I have done this many times over the years with non 'load bearing/out of sight' panels with no problems, it thickens and strengthen s the metal and it ain't gonna rust again! Ever.

- Norman Julian

- "Who was that masked man." Brilliant James!!!!!!!!

- To quote a character out of "F Troop".

- "I don't know why people say you are so dumb"! LOL

- James Leonard Garrod

- UPU2V

- Peter Velthuis James Leonard Garrod nice number plate i reckon.

- Alan Routh

- Get some hammer effects paint helps to mask it

- Norman Julian

- Good suggestion Alan but it is a floor panel and being like this would have weakened it so it needs filling to get some of the strength back.

- Then I will seal it with something and then put rubber over the whole area.

- Mark Ellery

- Same idea as James but stick solder

- Norman Julian

- That's exactly what I was going to do Mark but don't tell James. He will just call me an idiot.

- James Leonard Garrod

- Idiots ! Stick solder isn't hard enough unless you mix it with Viagra and it still won't stay hard forever!

- Norman Julian

- You're the idiot!

- Everyone knows you stick it with spit. Viagra has only been around for a short time.

- I was looking at it and thinking about the fact that soldering or brazing isn't going to give it much in the way of strength and the likelyhood of distortion is great, so I may bog it. I just went and had a look and it is still pretty strong.

- James Leonard Garrod

- He shall henceforth be known as 'Bogman' lucky his first name's not 'Peat'!

- Norman Julian

- Mr Bogman to you, fool!

- John Olde

- Take it to local Tafe and see if they will remake as coach-building exercise ?

- Adam Draper

- Have you considered lead wiping?

- If you can get the lead

- Andrew Blacklock Yes lead wipe is a good thought and you can buy kit to do it fairly cheaply.

- It's not hard to do either

- If you had access to a tig welder you could tig the holes up gently and then lead wipe and file finish . Use a piece of copper behind the hole when welding it.

- Norman Julian

- Lead wiping in this case is would be very time consuming. Conditions have to be absolutely meticulously clean from rust for the tinning to work. The amount of craters is quite a bit.

- Greg Scott

- I'd get a nice square piece of copper norm place it behind the pitting I'd set the mig on a low setting and pad weld up the lows then grind and linisher the welds ! You'll be surprised how quick and strong it will be ! Gas and wire isn't super expensive either !

- Andrew Blacklock

- I have found the inverter migs better than the transformer migs with the light gauze steel work

- Norman Julian

- After careful consideration I have decided to use filler. It has a reinforcing bar under it going from one side to the other, so there is still plenty of strength there. Filling it with lead or solder or even brass there is a chance of metal distortion because there is a great deal of filling to do and not really warranted. It will be covered with rubber.

- James Leonard Garrod

- You should be covered with rubber - the type with a great big zipper......

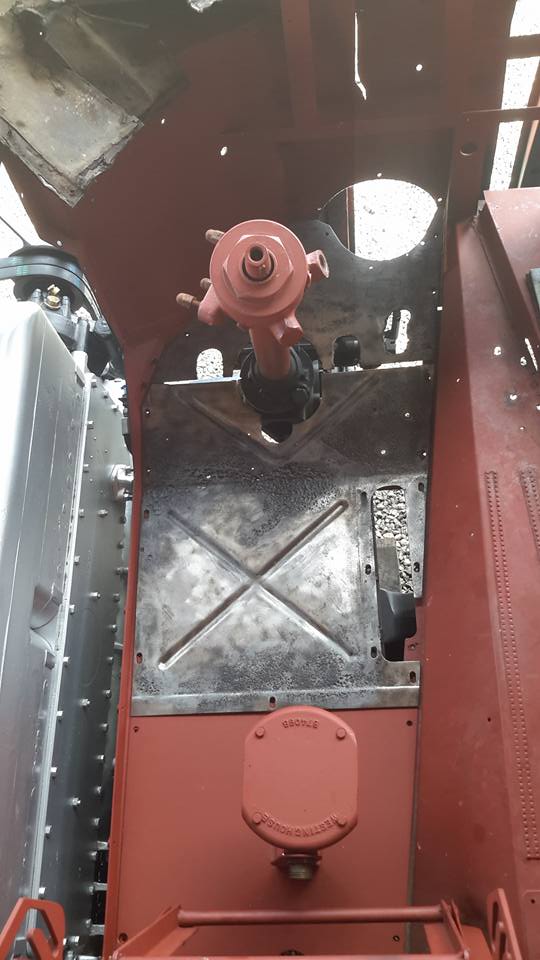

- These three separate panels make up the deck plates for the driver.

- One would wonder why a properly machine cut panel would have four roughly cut section cut the way they are.

- They were cut with an oxy.

- Very curious.

- 17th Feb 2017

- Norman Julian I didn't put this rounded shape on the top part of this plate back in.

- I'm sure it is to allow cables through but there is still lots of room in front for those things.

- Norman Julian

- This cut out looks like it is made for a headlight for a half cab design.

- It isn't needed in this case.

- I am re making this panel.

- The holes in it are way too big and really unnecessary.

- Because I am sound proofing the bus as much as possible, holes like this wont help

- 19th Feb 2017

- Driver's floor done.

- Now to put back the mechanicals

- Alan Routh

- Whats the Westinghouse valve for?

- Andrew Blacklock

- ejection drivers seat

- Norman Julian

- Regulator!

- Peter Velthuis

- Regulator for how heavy you are as to how much power you get ?.

- Norman Julian

- It's the air regulator for the whole system.

- Brakes, transmission, etc.

- Norman Julian

- If you have a gas bottle for a bbq you need a regulator otherwise you would have the first burner with all the gas and none for the rest.

- Same with the bus except air.

- Andrew Blacklock

- got to love the good old red primer = great stuff

- Norman Julian

- This stuff is good but not a patch on the lead zinc primer of old.

- Peter Kallenbach

- It doesnt have the main component that worked well Norman, LEAD

- Norman Julian

- With lead in the paint you didn't need top coat.

- With the primer these days moisture penetrates it fairly quickly and rusts from inside out.

This site is hosted on

Fatcow  Unlimited Web Hosting |

Last updated February, 2017 |

This web site may contain Copyright material If you find any problems with the site, please email the Web Editor  |