Norms Restoration - 31 Seater Projects |

1952 AEC Regal III [2547]

2017

October Body

- Norm

- 22nd Oct

- You have to forgive me for the angle of the back of the bus here.

- It is near a fence panel and can't get a front on shot.

- Yesterday with my welding practice I managed to finish this complex rear emergency door panel just below the door.

- I also have in place the rear panel that carries the indicator lights, stop light etc.

- Nearly every panel apart from the upper egg shell panels will be replaced.

- The other job was the pattern made from masonite for the side fixed window.

- John Lidstone

- lovely curves and nicely fitting rubber there.

- Norman Julian

- You can't rush these things. LOL!

- Carle Gregory

- love the "other" Leyland" next to it

- John Lidstone

- you really are making such a good job of every part of this.

- The 'frustrated restorer' in me is envious of your skills! :)

- I wish I lived around the corner, I could learn so much and offer a willing pair of hands.

- Jonathan Blackburn

- Good job so far Norman

- Anthony Christie

- Its a piece of Art!

- Norman Julian

- Thought you were going to say shit for a minute Anthony! LOL

- Anthony Christie

- God no.... I'd love your skill set!

- Norman Julian

- Sorry buddy. No skill involved

- Jonathan Blackburn

- Passion and Dedication in my mind!

- Anton Frank

- Coming together.

- Norman Julian

- 21 October at 17:03

- I tried my hand at welding aluminium today.

- My neighbor has a state of the art welder.

- I practised on 2mm stuff and at first found it a bit challenging but after a short while I could weld good enough but then I got to these bus bits and found this very different.

- I was blowing holes as easy as anything.

- Any contamination at all and you wont weld.

- Eventually though I could weld good enough to repair these panels.

- Having the right welder is vital.

- Welding this thin stuff with corrosion is really hard. I do though have a better understanding.

- Bret J Bistowski

- Tom says he can weld aluminum foil. LOL

- Norman Julian

- Yeah! The guy next door says the same thing. I just looked at him and said nothing. LOL.

- Norman Julian

- I am pretty handy with a mig and can weld down to .5 with mine but welding thin aluminium was a very different ball game.

- Norman Julian

- 21 October

- I have seen plenty of frogs that have cracks in this area just above the radiator.

- Norman Julian

- 20 October

- Norman Julian This is the new design.

- Norman Julian

- 20 October

- This is the original design.

- Norman Julian

- 20th Oct

- The reason I replaced this panel is because it had more holes in it than the Titanic.

- Norman Julian

- 18th Oct

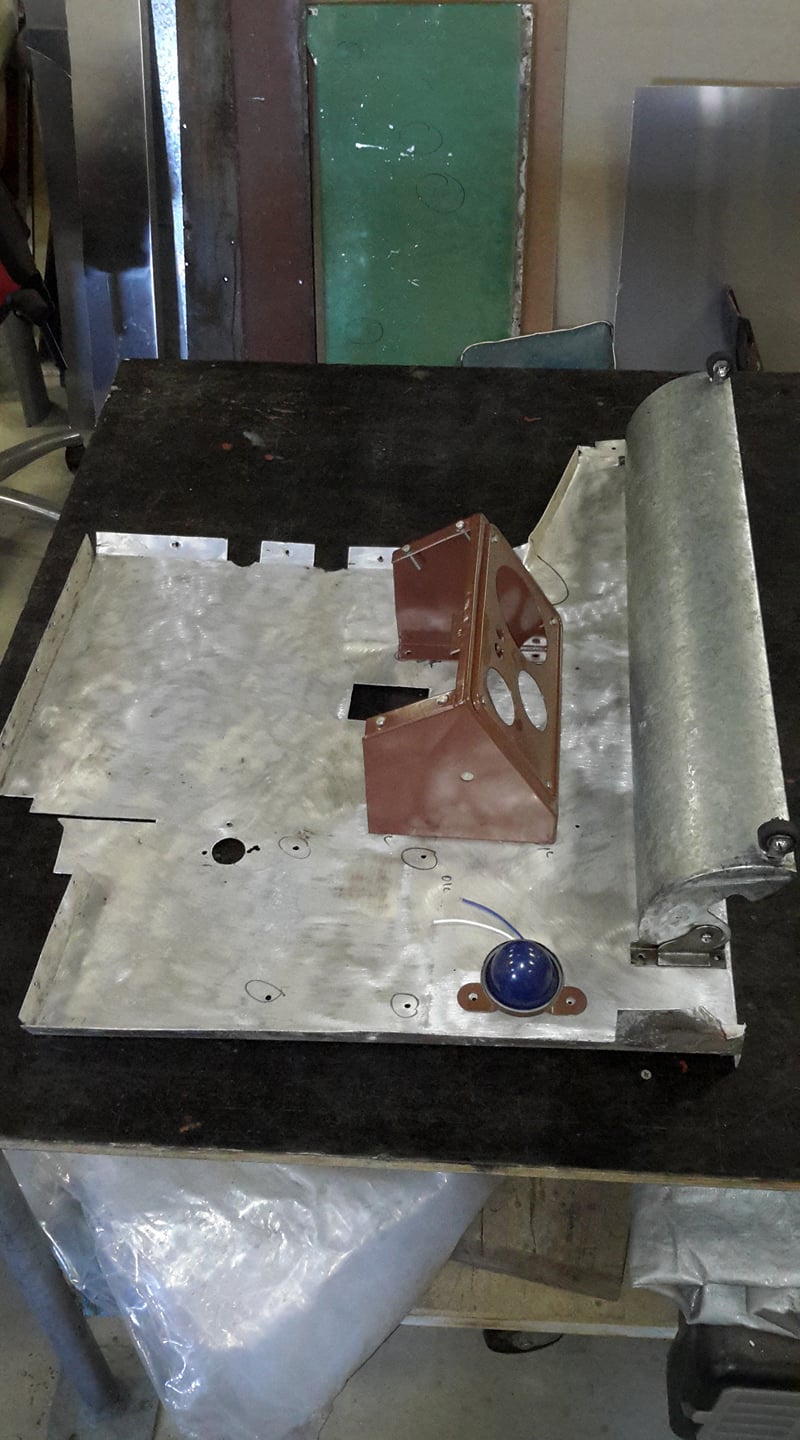

- I did a few things today like make this lower panel for the instrument cluster.

- The other is this fixed window panel.

- Because this window frame was falling apart with rust the complicated shape of the frame couldn't be exact when I remade it.

- I remember when I took this apart that it wasn't put together well.

- I spent a bit of time using the hammer and dolly to reshape some of the areas of this aluminium panel to fit.

- Aluminium is very easy to manipulate.

- It now fits exact.

- The old perspex they used never fitted properly so I will have to make a new pattern out of masonite and then can get a new window made.

- Norman Julian

- 17th Oct

- This is best described as the drivers console area.

- It has that wind deflector and other things like the dash and the cord bell light amongst other things.

- I have to get some repairs done to this panel as well as welding up any unnecessary holes over the years.

- Norm 17th Oct

- The last of the jobs I started during the winter.

- I will start outside on the bus again

- Peter Velthuis

- Haha before it get to hot.

- Norman Julian

- This believe it or not is part of the air conditioning.

- In fact it is the airconditioning.

- Norman

- 15 October

- I have moved on from the front windows and will revisit them when I'm in a better mood.

- I made this a few months ago because I couldn't find a decent replacement and the original was rusted badly underneath. I soldered together this front drivers wind diverter (that is what I call it).

- I will finish it tomorrow. I love soldering.

- John Lidstone

- your works are so good Norm. Well done.

- Norman Julian

- Thanks for the vote of confidence, John.

- Norman

- 15 October

- I cut these off a second series frog.

- I will adjust them to make them look original.

- Norman Julian

- 14 October at 16:12

- I'm happy to report that the second attempt worked.

- Using the thinner clear plastic worked.

- I didn't have to use mastic.

- Norman Julian

- This job in theory should be the easiest job of all but because I don't have the proper sealing channel it ends up being a challenge.

- Norman Julian

- 14 October at 09:03

- Not everything always goes according to plan.

- Garth Taylor

- Oh bother, or maybe some other stronger words!!

- James Leonard Garrod

- Bugger, sincerely pissed off on your behalf!

- Norman Julian

- Strangely enough I knew this plan was going south from the word go.

- The rubber was too tight.

- I bought some clear plastic which is a little thinner.

- Will be able to show you all by the end of the day.

- By the way that piece of glass was $90.

- 14 October at 09:12

- Frank Bugby

- O bother !

- Adam Woodwards

- Looks like you've had a cracking time...

- 14 October at 13:36

- Norman Julian

- If only I could get bailey channel to fit this size it would be installed in the time it takes to say "James Leonard Garrod is an idiot". LOL

- 14 October at 14:50

- Norman Julian

- 14 October at 10:00

- Another thing I am doing is changing these brackets.

- 3 out of the 4 screws holding the bottom part of the each window frame has stripped.

- The brackets and screws are brass which is a good or bad thing.

- In this case it is bad. I am replacing them with steel, so stripping the thread of something that is 4mm thick is unlikely.

- The only thing is that the holes in the frame are countersunk so drilling holes in the bracket and tapping them is crucial.

- If it isn't accurate the 2 ends of the frames wont come together flush.

- Norman Julian

- 9 October at 18:36

- Well folks! I'm baffled.

- I am frustrated because I can't seal these 2 windows.

- Unfortunately I never took notice or even remember what held these pieces of glass in.

- The problem is getting the rubber to sit still while I slide the glass down inside the frame.

- The bottom and top are OK it's the sides.

- If the frame came completely apart there wouldn't be an issue.

- The bottom end of the frame unscrews only.

- Has any of the older followers even done or even seen these frames done?

- Brian Hooper

- Scott Wilson will know

- Brian Hooper

- Or ill peak at the one at the farm

- Norman Julian

- Wont help Brian.

- I can look at the Leyland.

- Still no clues

- Norman Julian

- I need to get some "U" channel the same size as the glass.

- This special sealing rubber I got from Sydney reacts with anything liquid.

- I have to put it on dry and then it wont slide.

- Anton Frank

- Can you use spray silicon, as it is used as a release agent for rubber tyres and other things.

- James Leonard Garrod

- Chalk or graphite powder?

- Brian Blunt

- Best person to talk to is Peter Jackson at http://www.oldera.com.au/

- Old~Era Services Restoration supplies and Rust Repair Panels for older cars

- oldera.com.au

- Brian Blunt

- He makes most of the rubber bits that the other companies sell.

- I think you would need "bailey channel" in the frames

- Andrew Blacklock

- think it was a U material

- Norman Julian

- I'm think it was something easy to work with.

- Something semi solid that will still seal.

- Edward Parker

- There is a special glazing thin rubber you buy that you wrap around and stretch as you put window in then knife excess rubber off

- Norman Julian

- Yeah I was thinking that Edward.

- The rubber I was using is a special sealing rubber that when it heats up it seals but as I said it reacts with anything liquid so because of friction it wsn't going on.

- Edward Parker

- The stuff we bought was purchased through custom coaches they got it from melb its about 50mm wide memory and comes in a long roll i csn get a pic of it tomorrow if you want beclawatt used it on there sliding windows on trains and buses to fit aluminum strips onto glass

- Norman Julian

- I have these jacknife door rubbers that go on the side which has never been on a bus It is 1mm thick the size I need. I will experiment with that.

- Edward Parker

- I think its thinner than 1mm for mem

- Edward Parker

- I tried everywhere to get the stuff no one had it only custom

- Alan Routh

- There is a glazing mob out on the old wonderland site, m4 m7 junction. The name escapes me at the minute

- Brian Blunt

- I have spoken to our body repair guy about a couple of similar frames we have..

- What we did was to set the glass into mastic. Make up some small rubber "plugs" to go between the edges of the glass and the frame;

- glue them to the inside of the frame to support the glass vertically and stop it moving laterally..

- Fit the glass into the frame, put a few 1 mm rubber spacers between the faces of the glass and the frame to secure it in place, then use windscreen mastic to seal up the gaps.

- Leave it for a few days to set, then trim up the edges.

- This will leave you with a weatherproof seal and no chance of vibration.

- Norman Julian

- Thanks for enquiring, Brian.

- I have a few ideas and that was one of them.

- Geoff Jones

- a mate of mine just called in , his wife went crazy over some coriander she wanted in her meal last night , so he went to the garden and got some, not enough she said so out he goes again , then she says she doesnt feel like coriander anymore , women, crazy as usual, ...

- he is a windscreen fitter so i told him of your problem & he said if he put his wife in front of the bus the glass would jump straight into place , maybe you should try that ....lol...

- Norman Julian

- 12 October at 16:25

- Lord oh lord.

- If only I had a d/decker.

- I would only have to do this once.

- Norman Julian

- I have a new idea on how to do this and a lot quicker.

- Norman Julian

- 8 October at 16:55

- A rare failure today.

- The rubber I got from Sydney a while back for the 2 main front windows wont do the job I wanted it for.

- The other thing that wont do are these 2 angled brackets.

- They assist to hold the bottom frame to the rest of the window.

- Because they are made of brass they strip very easy when too much pressure is applied to the screw which is what happened here.

- I have had to fix lots of stripped threads from the start of this project I just hate days where you don't make much progress.

- Robert Bothwell

- Old vehicles can be character building.

This site is hosted on

Fatcow  Unlimited Web Hosting |

Last updated Oct, 2017 |

This web site may contain Copyright material If you find any problems with the site, please email the Web Editor  |