Norms Restoration - 31 Seater Projects |

1952 AEC Regal III [2547]

2018

January Body

- Norman Julian 2nd Jan

- Sorry but couldn't help myself.

- The way it was wasn't good enough.

- The standard is as such that it took me 2 days to get it satisfactory.

- Graeme Knappick

- Perfection.

- Gregor Neil Robertson

- Well, it don’t come no better (great coachwork in old Edinburgh trams, all scrapped ‘56)

- Charles Shipway

- Fantastic trades mans like finish and worth the effort Norman

- Norman Julian 13th Jan

- Sorry for the poor quality photos.

- Not sure why it has happened.

- Anyway, I pulled apart these panels and welded up the old rivet holes the old panels used to go into.

- Never have much luck drilling new holes in the new sheets and getting them to lign up again, so I think it is easier to start again.

- With this part of the build I have been fixing up all the rough work that was done in building this bus in the first place.

- Most I have spotted and fixed along the way but the occasional one I have decided to leave mainly because I have proceeded too far before I noticed and it's a little late to go back to fix.

- Doing this section I have had an avalanche of things and its annoying. If I know there is something I'm not happy with it eats at me till I do something about it.

- Sometimes to cure my ailment it can mean a lot of work.

- Anyway, after nearly 2 days work it is about 90% acceptable.

- I am looking at replacing the top capping that goes on the top of this bulkhead wall because it is dented quite badly and will spoil the rest if left.

- The blue bell lights at the roof level are wired up and the cable is out through the top roof bow ready to be wired in properly at another time.

- Norman Julian 15 Jan

- This is a typical Overhaul done every few years on the entire fleet.

- Charles Shipway

- Like the photo.

- Norman those of us in the industry take shots like this for granted but this shot is a wonderful memory of what happens to well maintained buses

- Norman Julian

- Yeah!

- I would like more but rare as hens teeth.

- Andrew Blacklock

- Any idea of photo location?

- Norman Julian

- The majority of the major overhauls were done at Chullora Workshops.

- Bob Gioia

- Definatley Chullora.

- Only other place that overhauled buses was Gordon Avenue in Newcastle but they did not have a production line set up like in this pic.

- Andrew Blacklock

- Thought so, thanks

- Norman Julian

- There were some minor overhauls done at depts.

- I heard this sometime ago.

- Maxwell Mcroberts

- I worked there mid to late 70s

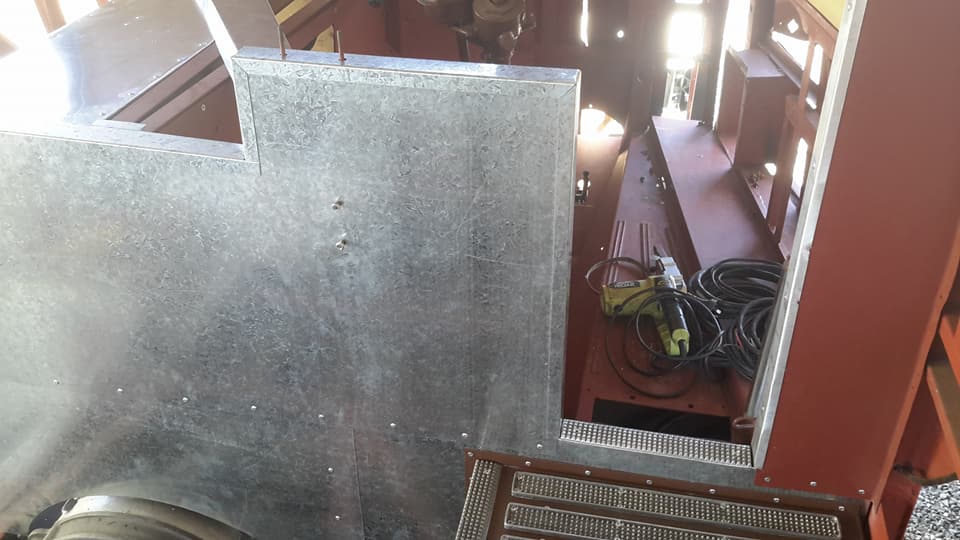

- Norman Julian 16th Jan

- This bulk head wall has been trying my patience from the very first day I started working on it.

- Firstly the near side section was completely rusted out which meant it had to be rebuilt.

- The drivers or off side had to be rebuilt at the top because of an accident it had at one stage in its life and was badly repaired.

- The roof in that area had dropped about 50mm which meant cutting the roof bow and raising it the 50mm needed.

- Then the panels on either side at the top had to be remade to allow for the increase in size.

- With all this done the panels are a little tight and have to be adjusted.

- With all the panels in position I decided to replace the capping on either side.

- The original capping was aluminium and badly dented so I decided to replace it with 1mm galvanised steel mainly because it is more hardy.

- Gregor Neil Robertson

- Really beginning to see the form now, at last.

- Looking forward to seeing a roof go on - be careful, you’re about to start working heights!

- Norman Julian 17th Jan

- Todays jobs.

- I finished the capping on the back bulk head wall.

- I also put back in the drivers step.

- Originally pop rivets were used that just went into the sheet steel which obviously were ok but I reinforced the front bulkhead wall behind this sheet steel where the rivets were with some 3mm steel.

- I still used pop rivets but now they have some meat to bite into.

- Norman Julian

- Here is this step from another vehicle

- Norman Julian 17th Jan

- Just a question for those that may know.

- Here is a few pictures of the back bulkhead wall near the back door with the conductors button.

- In these pictures one other bus and this one had a small riveted patch covering a hole that was once there.

- When I took the paint off mine I welded up that small hole.

- I am curious as to what this was.

- Was it a toggle switch to manually open and close the back door for the conductor or something else.

- There was wiring on mine that was taped up.

- If you look at the photos you can see the patch.

- Brian Blunt I think it was a switch to isolate the back door operation when the bus was run OPO.

- Or perhaps more appropriately to un-isolate it if there was a conductor on board.

- David Wilson

- I think it was a switch - never seen it in a photo.Ignore it

- Brian Blunt

- They were also in the u/fs, a pull/push switch. I can remember seeing them.

- David Wilson

- you need that 2866 for parts

- Norman Julian

- That's the one at Gilgandra. She is far too good to wreck.

- David Wilson

- can't preserve them all -2818 is more important

- Norman Julian

- If the bus was full and had a conductor on he could close the back door without the risk of closing it on a passenger. When they became wholly driver operated they weren't needed anymore.

- What's more people couldn't open them while the bus was moving.

- Norman Julian 18th Jan

- I started the replacement capping for the front bulkhead wall.

- Replacement foot grids as well.

- The old capping was dented and cracked.

- Norman Julian 19th Jun

- I have finished in this area for the time being.

- The capping turned out well and I'm glad I made the engine cover 10mm wider than what it was, it now looks good with the gap being closed up a little.

- Norman Julian 22 Jan

- Because I had changed some of the aluminium for galvanised steel I thought I had better go and study the results and potential pitfalls with mixing these 2 metals together.

- The short answer is there can be problems with these 2 metals being mixed together.

- Mainly it is the zinc in the gal that can react with the aluminium but the problems can be either minor or major depending on where you are living.

- If you are living on the coast the problems could be greater with the added problem of salt in the air.

- The problems in rural areas such as where I am is very low.

- Apparently the salt content can speed up the corrosive effect of the 2 metals being in contact with each other. Problems can be reduced if there is an insulating barrier between the metals such as paint for instance.

- There is still a risk with aluminium over a long time with the aluminium rivets reacting with steel products but they are so small and take so long that it isn't worth worrying about, but if this problem occurs near the coast the risk is far greater.

- This makes sense to me because both 2818 and 2547s pop rivets have corroded to the point where they have let go.

- 2818 has panels coming off everywhere.

- Most of it is because of rusted steel framing but there are quite a few rivets that have failed with corrosion.

- Craig Parkinson

- Plus the added weight of it. Told you before leave it as it was. Now learning the hard way!

- Norman Julian

- The only thing that I have changed from aluminium to steel is the capping around the front bulkhead wall and the rear bulk head wall

- It is 1mm thick gal steel.

- The weight is negligible.

- The aluminium was dented and splitting.

- Everything else is still either steel or aluminium.

- The bus will be sheeted in aluminium.

- There is no sense in sheeting it in gal so was never going down that path.

- So your comment is a little baffling.

- Lorie Norton

- I have swapped from aluminium to colour bond, when they rescheduled the bus bay used actual colour bond pop rivets to secure the sheets to the steel framework.

- Unfortunately they won’t line rivets but they should be okay for the application I hope.

- Greg Scott

- a squirt of butyl mastic between surfaces !

- Noel Redden

- Its called galvanic corrosion & it is how batteries work - dissimilar metals & an electrolyte with the anode corroding. There is a chart available which shows how different metals will react.

- Al, Fe & Zn are all very close on the chart so they are the safest to use together & yes any sort of insulator will prevent it.

- John Lidstone

- I saw this in a Watsons Greys Albion, which suffered galloping corrosion bee case of the metallic mix.

- Similarly, steel beads on the local heritage livery Trident is blistering and corroding badly with the reaction between this and the aluminium panels to which they are attached.

- Norman Julian

- In your harsh road environment corrosion can be an issue with these metals being together.

- John Lidstone

- true the dampness plays a role without doubt

- Norman Julian

- John Lidstone More the salt!

- Royce Webster

- Just replaced some window winders where electrolysis had eaten alloy away on window frame.

- Aluminum windows, alloy supports and metal screws. Add a good dose of salt air and in the end nothing left.

- Norman Julian

- Yeah!

- Different metals and conditions, equals different results.

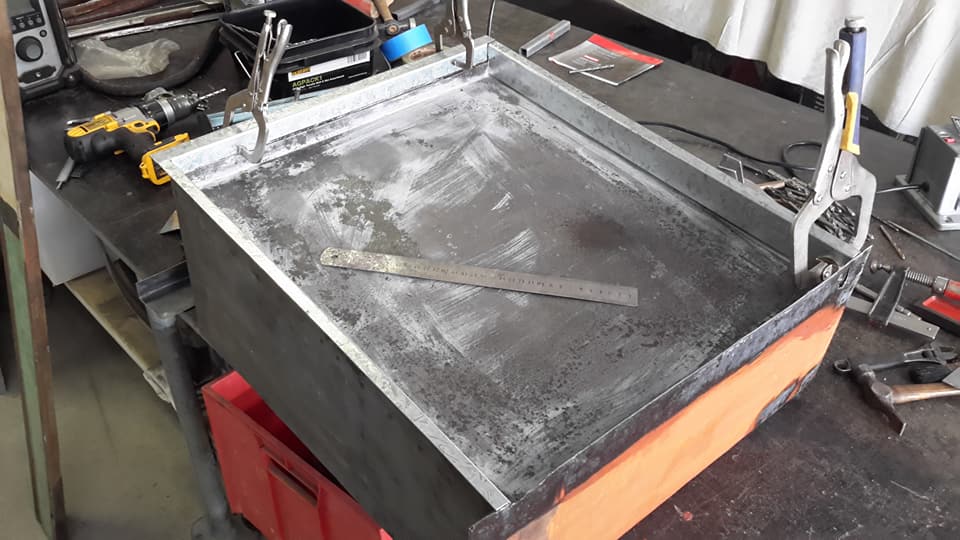

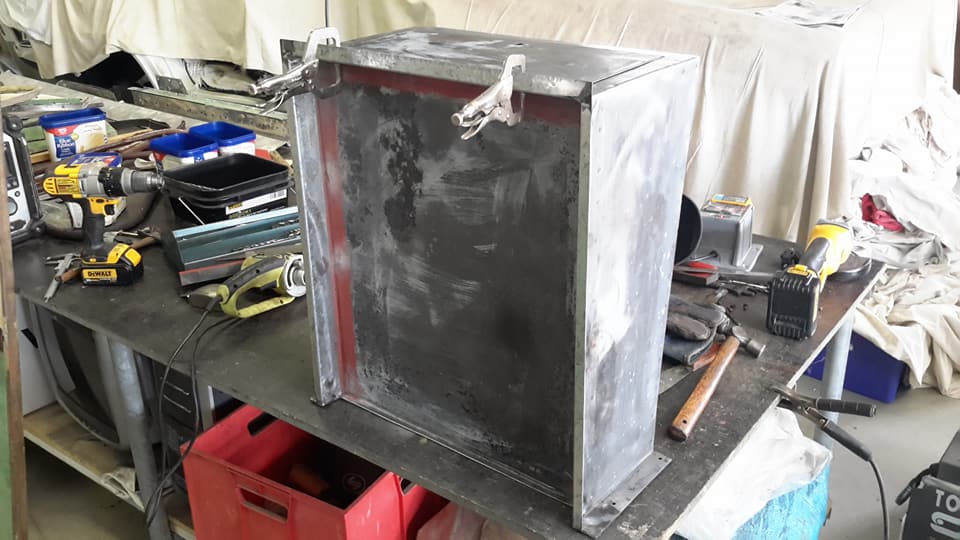

- Norman Julian 24th Jan

- Who do we have to thank for rust. This is a utility box (that's what I call it).

- It goes under the 3 seater adjacent to the driver in the saloon area of the bus.

- What was it that someone said to me some time ago anout this bus " She's pretty clean.

- Wont have to do much to her"!

- Norman Julian

- Least I know which day this box was made.

- Bloody Friday.

- Sorry, hate sloppy work!

- Philip Tumber

- Was used for driver and/or conductor to store valuables, complete with "route key" lock.

- Brian Blunt

- They had boxes like this on the trams, and the cleaners used to sweep the tickets into them at night.

- We found lots of really old tickets that way

- Norman Julian

- Rebuilding this is underway.

- Greg Scott

- they were dead right norm !

- youre bus had very little rust !

- Norman Julian

- Your bus has got nothing on the Leyland.

- LOL

- Stuart Brown

- I would molasses bath that.

- Norman Julian

- It's done Stuart.

- Norman Julian 24 Jan

- Memories of 5 years ago

- In Mullion Creek, New South Wales, Australia.

- John Lidstone

- looking great - your bus will be quite something when you've finished.

- I'd love to practise and learn new skills with someone such as yourself as I enjoy restoring things

- Norman Julian 27th Jan

- Replaced aĺl the rusted folded ends and used rust converter after taking off endless coats of paint.

- What's the cure for rust coming through the paint. Just keep on painting.

- Norman Julian

- The lock on this box looks rusty but it is only dirty with surface grime.

- I now soak these parts in a solution and they come up well.

- What I used to do was to wire brush them and that destroys the zinc protection and they start to rust,so if you want to bring them up OK just soakvthem in c a chemical solution that desolves dirt and rust.

- Chris Dempsey

- Acid does wonders Norm ��

This site is hosted on

Fatcow  Unlimited Web Hosting |

Last updated January 2018 |

This web site may contain Copyright material If you find any problems with the site, please email the Web Editor  |