Norms Restoration - 31 Seater Projects |

1952 AEC Regal III [2547]

2019

Body January

- Norman Julian 1st Jan

- Message for Charles Shipway.

- You should be down in my shed sucking up the fumes of the cypress.

- You will have to bring your own banana lounge and a few feers wouldn't go astray.

- LOL

- Rick Gotley

- Love the smell of Cypress, i have 2 trades , Mechanical Engineer , Cabinet maker

- Charles Shipway

- Enjoy laying the floor blokes Iím looking forward to see it finished BUT donít rush will you ?

- Charles Shipway

- Norm Thanks for the offer it is very kind of you and if only we could make it happen would make me so pleased BUT now Iím in care the physiotherapist gives me treatment four days a week to keep me moving Oh the joys and pleasures caused by maturing Iím sure you understand ?

- Marea Julian

- He sure does!

- Norman Julian 1st Jan

- I'm enjoying working with timber again though my bung hip isn't thanking me.

- Not much straight cutting but I'm pleased with the result.

- Very grateful that balancing over bearers is almost over.

- Fred Holland

- Looking very nice Norm.

- Charles Shipway

- Norman Iím rapped in the detail you have created those steps are perfect in every way And for the rest it is good to see it coming on

- Stuart Brown

- Very nice!

- As I noted before will be a shame to cover that up though I know that unfortunately that is how it has to be

- Norman Julian 2nd Jan

- Small amount of progress today.

- Probably 2/3rds the way through.

- Having a little bit of trouble marrying up the board sizes to make them fit properly.

- When butting end to end there is a 2mm difference in some planks.

- Doesn't sound like much but makes a difference with the one next to it.

- I have to deal with the planks going next to the tank filler tube.

- Can't speak for all 31 seaters but this one there was nothing to screw the floor plank to right up to the filler neck as you can see in the picture.

- I think I will weld an angle from one part of the frame to the outside wall, so as to support better the end of the floor.

- Norman Julian

- You can see in this picture the filler neck comes up and is higher then the floor level.

- There is nothing to support the floor.

- Norman Julian

- I guess they were relying on the tongue and groove design of the floor to support its neighbour.

- There is only 3 boards affected.

- Brian Musgrove

- I would glue a support underneath

- John Clarke

- So, Norman, do you then coat the floor in whatever it was? From memory, it almost looked like ashphalt.

- Andrew Blacklock

- Polished floor boards look good on it

- lol

- Norman Julian

- I'm not polishing the floor.

- If I was I would have ligned up the hatch doors pattern with the rest of the floor.

- Alyson Parris

- Amazing.

- Looking good.

- Brian Musgrove

- I remember travelling on these when i was a kid, and they had black floor , like Tar or Lino beats me!

- Norman Julian The floor will be covered with a bitumous product called Malthoid.

- First you paint the floor with a sealer then stick the malthoid down which is about a metre wide.

- It comes in rolls so easy to lay but very messy.

- This waterproofs the floor.

- Remember these buses were washed out with hoses so the floor needed to be waterproof.

- Norman Julian

- Back then the Malthoid used to be a lot thicker.

- These days the Malthoid is about half the thickness but I should be able to get away with one layer.

- Adrian Spencer

- What a waste of good looking boards.

- Making and Aussie Icon

- Norman Julian

- I am not having this conversation.

- It is a bus not a designer home.

- You don't use screws and certainly not seen with exposed flooring.

- It would look ridicilous if I left it like this.

- Norman Julian 3rd Jan

- A bit slow to get going today.

- Ran out of screws so went to Bunnings then came home to put this bar in.

- Not sure why it was never sorted out originally.

- Maybe because it is under a seat and it really never became an issue.

- This bar wont be a problem if the tank ever has to come out again.

- Now though the floor has something to hang on to.

- I recycled a piece of 50 x 50 angle from the far back wall from a few weeks ago that was bent on one end.

- Gregor Neil Robertson

- You've reached a good stage in the project.

- Great to see it like this. The coming together of metal and wood.

- Final big step will be trim, electrics and saloon interior coachwork - are you going to do all that too?

- Norman Julian

- I take it one step at a time Gregor.

- Probably will.

- Stuart Brown

- Do the seats just attach to the timber floor or are they more substantial than that Norman?

- Norman Julian

- The horizontal bar just up from the floor on both sides is a fixing point for the wall side of the seats.

- They are bolted at that point.

- The internal side or isle side of the seat is either screwed or bolted to the floor.

- Norman Julian 4th Jan

- Almost there.

- Just have to finish around the back door and make a new fuel neck cover, and do it slightly different from the original.

- Gregor Neil Robertson

- Very impressive!

- This is an exciting stage.

- We look forward to watching window installation - challenging.

- Norman Julian 5th Jan

- This mornings effort.

- Better conditions for working.

- Brian LeQuesne

- Keep them coming Norm - enjoying the progress.

- When you are finished old mate, I may have a re planking job at Wahroonga in my Kitchen for you.

- You seem to know what you are doing - as compared to the "professional" Roosters who put our Spotted Gum/Blackbutt floor in five years ago - that has to be redone.

- Norman Julian

- Off side and near side rear is now done.

- Steven Parrinder

- It is coming along well.

- looking good Norm.

- Garth Taylor

- Fantastic.

- Geoff Jones

- coming together very nicely Norm...ÖÖÖÖÖ..

- Norman Julian

- Thankyou boys

- Charles Shipway

- Well norm another job done well

- Norman Julian

- Thanks Charles!

- Fred Holland

- Fantastic job Norm.

- Where has that fuel intake pipe gone.

- Norman Julian

- Still there Fred

- Gregor Neil Robertson

- That's perfect ... you missed your vocation - or are you a cabinet maker to trade?

- Now put down a Welcome Door Mat.

- I'm dreading the challenges facing you installing the windows,��

- Charles Shipway

- I am waiting for the windows to begin my self A totally new project and when finished another job completed ready for the next move

- Phil Steele

- ��

- Norman Julian 6th Jan

- Done and dusted.

- Greg Scott

- well done norm great progress !

- i would dearly love to copy this pic and post on my site that ive been very busy over christmas !

- lol just a thought i never would !

- lol

- Norman Julian

- Go right ahead.

- Norman Julian

- Have you looked at your floor Greg Scott.

- What's it like?

- Greg Scott

- i cant lie !

- my floor is surprisingly about 75 percent intact !

- once my roof is done all the floor will be ripped up and i will renew most of the floor beams !

- i will follow in youre foot steps norm and renew 100% of the floor !

- Norman Julian

- My floor was 100% intact with no rotting.

- Can't say the same about the bearers.

- The ends on both sides of about 50% of them were rusted out.

- You cant replace a section without the floor being in the way.

- Anyway, by ripping up the floor gives you proper access to everything.

- Robert Bothwell

- Looks great.

- Berrick Owen

- Well done

- Steve Hardie

- Beautiful

- Rick Gotley

- Well done , looks good , shame to cover it with Malthorde

- Wayne Swadling

- Wow looking good

- Anton Frank

- Top job ������

- Gregor Neil Robertson

- Aha - is it really dusted?

- Now apply the polishin wax!

- On your knees!

- Anyway that's great.

- Can I book a night's sleep in it please?

- Charles Shipway

- Norm the detail you put into the floor is fantastic definitely a trade mans like finish thatís for sure

- Norman Julian 7th Jan

- Screwed off and cleaned up.

- After a week on and off.

- 125 lineal metres of 135 x 19mm cypress pine and about 250 screws.

- Steve Hardie

- Beautiful finish.Norman

- Graeme Knappick

- mmmmmmmm nice!

- Stuart Brown

- Normanís temporary mobile dance hall ��

- John Clarke

- Great job, Norman, now for the malthoid!

- Anton Frank

- See you in a couple of weeks to inspect your work.

- Gregor Neil Robertson

- Looks absolutely perfect.

- Would be a superb dance floor.

- Norman Julian 10th Jan

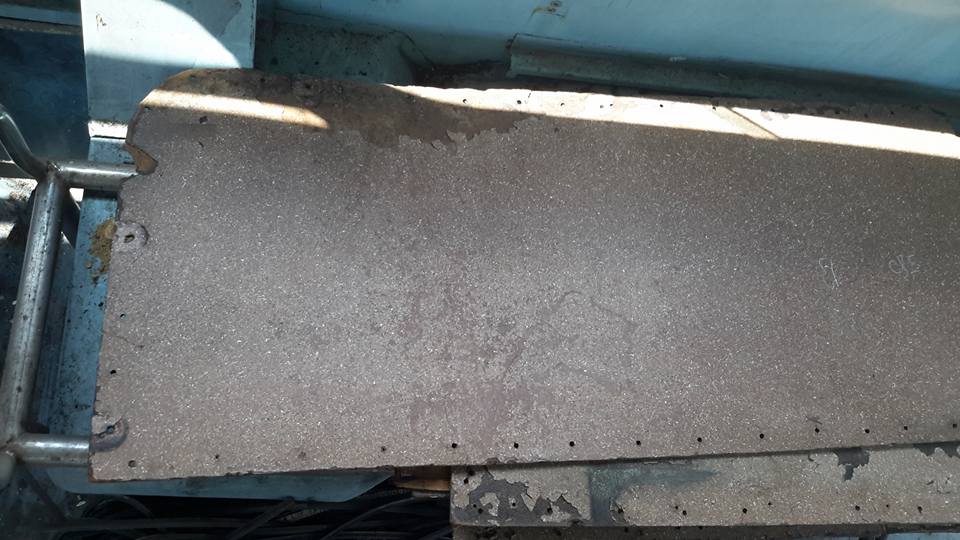

- Since the finish of the floor, I have been busy catching up on other chores around the house but I have organised new bottom kick plates for the bus as you can see in picture (the semi rounded sheets of metal).

- I also put the new section on the rear wall under the rear seat back.

- The new rear seat back is in position for trialling.

- I will be remaking all the internal wall panels as you can see which is made of masonite.

- It is hard to pick good quality masonite these days.

- Most will warp on you.

- I will also be painting them with a special mottling paint which is still available.

- I have been holding off getting it.

- Most of the ones in this picture have just been painted brown.

- Pretty much what they did during overhauls.

- I did take a shot of the mottled effect when they were brand new.

- Norman Julian

- This is the 2 items roughly in position.

- Charles Shipway

- Norm it is coming along well !!!!!!

- Good on yah

- Norman Julian

- The back piece that was replaced

- Norman Julian

- Not a very good example but you get the picture.

- Stuart Brown

- If you give the Masonite a coat of acrylic clear before you fit it that will seal moisture and reduce the risk of warpage.

- We do this with door trims and have also made bench tops from MDF like this very successfully

- Greg Gibson

- A clear coat of sealer will lock away any chance of any natural colours/oils etc bleeding through the undercoat.

- We do this at work with any timbers or plywoods before we undercoat them and then paint a top coat colour.

- Drying and sanding between coats of course.

- Charles Shipway

- Itís the Garden knome from over the coast here Norm it could be a help over time to ensure a good coat of sealer is painted on the sheet ends.

- As well Some times all it takes is a very small spot to be missed and destroy a good sheet itís time for me to find a nice warm spot in the garden and take a rest

- Norman Julian 12 Jan

- Tomorrow's job is to weld these seat bracing plates onto each wheel arch.

- One plate holds one side of the seat.

- One seat frame is finished with its cushions and the other is yet to be painted.

- Charles Shipway

- Looking more like Bus Norm

- Gregor Neil Robertson

- No sitting down on the job now....

- Rick Gotley

- Looks good !

- David Meddows

- Coming on nicely.

- A labour of love

- Norman Julian

- Extra insurance.

- If the weld fails (doubtful) then it is screwed in.

- James Leonard Garrod

- Norman Julian that big Road Sign in Victoria that fell on that Woman's car this week was also Welded AND Bolted ya Idiot.....

- Norman Julian

- James Leonard Garrod That's just a sign of the times!

- Norman Julian 14th Jan

- I would like some help or advice by some of you enthusiasts out there.

- This rubber piping is what was used around the rear bulkhead wall, just for dressing up purposes.

- It is round, with what looks like a 3/8" hole.

- The piping is pretty solid and is 7/8" or 22mm in diameter.

- I haven't got a clue where to get some.

- I have tried looking for a solid rubber replacement but have had no luck there either.

- One section is OK but the other has been heat damaged and is as hard as nails and not flexible anymore.

- Not sure what it was originally intended to be used for.

- Maybe early hydraulic hose.

- I need something solid that I can screw in to, but soft enough to bend around corners.

- Suggestions are welcome.

- Robert Bothwell

- Brown irrigation piping might be worth looking at - has very tiny holes in it - used for underground drip system.

- Bryce Pender

- Have you tried soaking the piping in hot water to soften it?

- Norman Julian

- It's heat damaged as well Bryce.

- Geoff Jones

- what about your local windscreen guy ..he may have something...Ö...

- Bryce Pender

- I was thinking the heat may soften it to allow repairs or reshaping, back in the dark depths of Hades (opps memory) we used to soften rubber fuel piping to make fitting easier

- Anton Frank

- Look up Mackay rubber.

- They do heaps of rubber hose/tubing. not just mounts.

- Norman Julian

- No go with that company, Anton Frank.

- I got a reply this morning.

- They can't help.

- Thanks for the suggestion.

- Paul Melling

- Can you use the rubber that you use to hold in a flyscreen?

- Norman Julian

- Flyscreen rubber is only 6mm thick

- Paul Melling Fuel hose?

- Greg Scott

- I havent crossed that path yet norm but to me it looks near identical to garden hose

- Norman Julian

- Garden hose is too soft and the wall isn't thick enough and wrong diameter.

- Apart from being completely unsuitable it's perfect.

- LOL.

- Greg Scott

- Norman Julian sounds great norm ? Lol

- Norman Julian

- This is it in position.

- One of those Friday afternoon ideas me thinks.

- LOL.

- First you have the rubber piping then aluminium quad to finish it off and to me it looks amateurish.

- The later models went away from this idea.

- Terry Weblin

- There a place called riga rubber they make most things from rubber at Weatherill.

- Park N.S.W

- Gregor Neil Robertson

- Commercial vehicle hydraulic hose.

- Could be too tough though to cut the slot for glass in a straight line.

- Possibly soft plastic for shower cabinet glazing sealing from plumbers merchants?

- The right item will be out there but needs searching for.

- Good luck.

- Norman Julian

- There is no glass in this frame Gregor.

- Just piping

- Gregor Neil Robertson

- Norman Julian we look forward to seeing your solution ...

- James Leonard Garrod

- Ask that Idiot Maher for a contact re hosing.

- I have worked with his pressure/steam washing equipment and it 'looks' to be the same as your example.

- His is slightly larger BUT he should be able to steer you towards a supplier with a variety of sizes.

- (NB: this is a Serious reply, rare occurance I know, but I will even help an Idiot if ot's for a good cause...)

- James Leonard Garrod

- What Size is Oxy/Acetaline hose? (and it comes in two colours.......sometimes I just Amaze the Shit Outta myself about Myself!)

- Anton Frank

- Yeah, and flame arresters would be the Ultimate Bling....��

- Norman Julian 16 Jan

- I just picked up the replacement kick panels.

- There is one roughly in position.

- Charles Shipway

- Oh I know Iíve probably said it before photos such as this one are good to see what comes next is a good feeling to get an idea of how the partly finished job will look before being covered With the final finish

- Norman Julian 16 Jan

- Norman Julian

- These panels get screwed to the floor and the wall.

- Malthoid then gets laid on the floor and laps over the top of the panels.

- It acts as a form of waterproofing for the side walls.

- These buses would have been regularly washed out with a hose so the idea is to limit the amount of water penetration.

- Norman Julian 18 Jan

- These are 3 of the extensive range of examples available to do the backs and wall panels on the bus.

- The one I'm using is the one at the bottom.

- It is about 90% accurate.

- Bob Gioia W

- hat brand Norm?

- Norman Julian

- David Wilson has all the details, Bob Gioia

- Norman Julian 23 Jan

- I have just placed the bottom kick plates in position here for the moment.

- Firstly, I had to allow for this box to be put in the exact spot before I cut the panels to size.

- Even before that I had to put the bench seat in the exact spot.

- The box goes under the seat and there is no room for ajustment.

- I spent quite a bit of time making this panel that forms over the top and around the fuel filler tube down to the wheel arch.

- It was done in 2 pieces originally.

- Gregor Neil Robertson

- When the omnibus resumes service, I hope all its passengers appreciate your thoughtful comforts provided!

This site is hosted on

Crazy Domains & Hosting  Unlimited Web Hosting |

Last updated January 2019 |

This web site may contain Copyright material If you find any problems with the site, please email the Web Editor  |